The truck had a major blowout a couple of years ago. I was driving over Monarch Pass in Colorado hauling the camper and trailer when the transmission gave out on the downhill side. It was on a Sunday so it was $450 to get towed 9 miles to the Gunnison KOA. I called some friends and one buddy came up with his car hauler and another buddy with his truck and grabbed my trailer. They towed me back down to the house I was working on and the truck sat until I was able to get to it. I traded some work for a 1999 Subaru Outback to drive around while I worked on the house and contemplated what I was going to do to fix the tranny.

I considered swapping the tranny for a manual, I’m really not a fan of automatics but ultimately settled on rebuilding my existing transmission myself. I’m not a mechanic but I’ve done some pretty major automotive repairs in the past like engine rebuilds and steering/suspension overhauls as well as a few other projects. I believe you can learn anything from YouTube so I set out to find some good videos and found a website put together by a long time transmission mechanic, Transmission Bench. He sold a rebuild kit and a video set that was very detailed and while I might have been able to source the parts cheaper, I bought the initial rebuild kit and some other parts from him to support his business.

Research Videos:

I’m not in anyway associated with any of these YouTube channels or Transmission Bench but I found them useful in this project.

Removal Notes:

Pulling the transmission was a project. My buddy that helped me with the cabinet project also allowed me to use his shop to work on this project. In order to get the transmission out, I had to remove the drive shafts, the front part of the exhaust, the torsion bars, T case, and everything connected. I tried for hours to get it out without removing some of this stuff but once I submitted everything came out pretty easy. I rented a torsion bar tool from O’Reilly’s but I had most of the other tools needed.

Tools and Jigs:

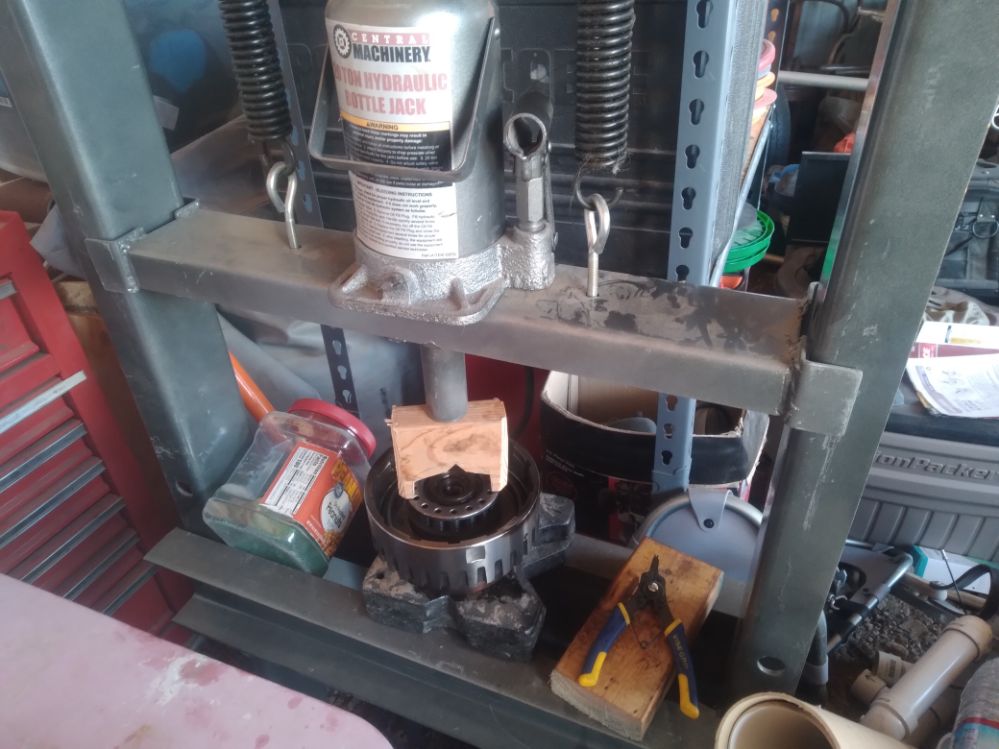

With the transmission out of the truck I built a couple of jigs to hold the tranny while I rebuilt it. The videos from Transmission Bench had the details to build a few simple jigs out of 2″X4″s that really made the project a lot easier. The videos also had specs for home made spring compressor but I had a 25 ton shop press from those steering/suspension projects, so I made some blocks out of wood to compress the springs. My buddy had a catch pan made from 2″X4″s and EPDM that helped contain the tranny fluid as I tore it down. Aside from these jigs and the torsion bar tool there were no other special tools needed for this rebuild except for an inch pounds torque wrench that goes up to at least 250 in pounds.

Parts:

Starting out, I purchased the rebuild master kit for my vehicle from Transmission Bench which came with the video package. I also bought the Transgo reprogramming kit, AFL repair kit with reamer, rear main seal and oil pan kit for the engine, and all new U-joints and center bearing. As I tore into the transmission I found other parts I needed to replace but I’ll go into that later. I bought the eco friendly mineral spirits and I’ll just say I’ll never use it again.

For decades I’ve said I would never touch a transmission, mostly just echoing what most car people say really. I have done several other projects that were just as involved as this one. I wouldn’t have attempted it without a good video to follow and the one put together by Transmission Bench was very detailed. It can be slow at times but he picks up every part and demonstrates how it comes apart and goes back together. He shows how to do the modifications for the Transgo kits and explains the basics of how and why things work without getting too much into it. I rebuilt my first motor (22R out of an 85 Toyota Pickup) in the mid 90s using a Haynes manual following step by step and this was much easier.

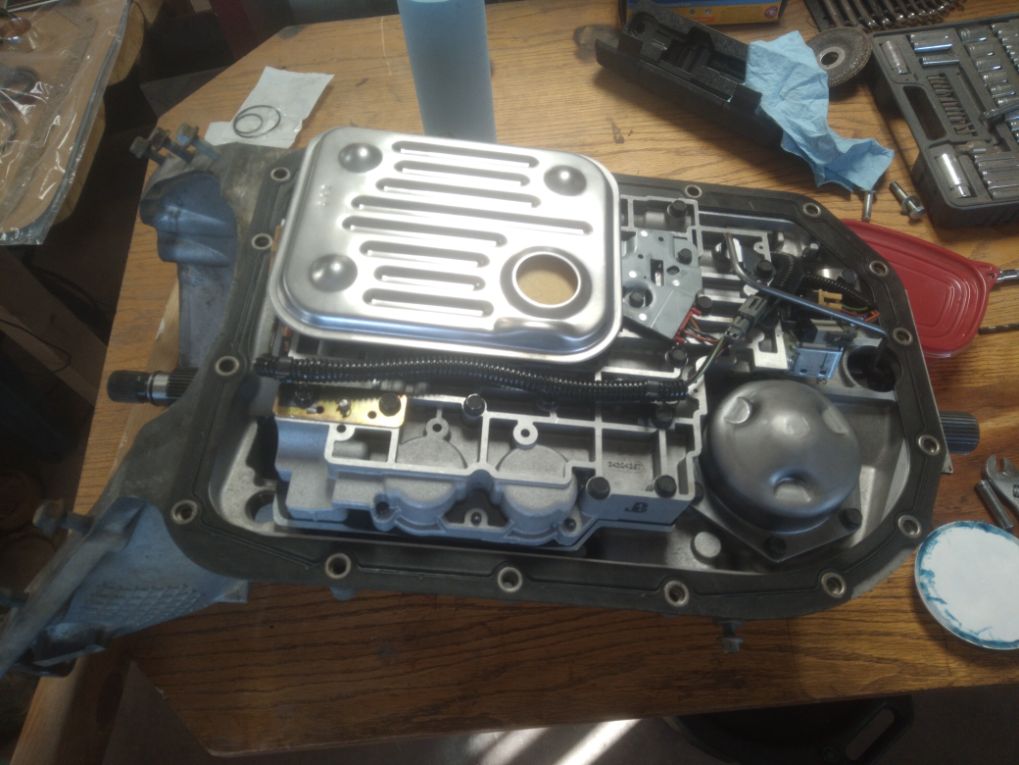

Once I got the transmission apart I found that most of it was in pretty good shape but there were a few things that had to be replaced. You always hope to find a smoking gun when it comes to a big rebuild but while I found some wear and tear I didn’t find anything that I could point to and say “there it is”. That said there was some parts that definitely needed to be replaced Just nothing that was a definitive reason for all out failure. I’m really glad I rebuilt it myself and I feel better with the heavy duty shift kit installed considering I haul a trailer and camper around the mountains of Colorado about 90% of the time.

So, while I didn’t get a smoking gun for the overall failure of the tranny I did have at least one “there it is” moment. I have never owned an automatic before this truck. I’ve always driven stick and even had a CDL and drove 80k to 120k lb trucks for Halliburton for a while. I downshift when going downhill to save the breaks and a bit before the tranny went out, 2nd gear stopped working when I manually downshifted. As I was working through the videos and we got to the point where you pull out the intermediate band, he makes a statement about how it is likely to have no signs of wear because all it does in engage 2nd when you manually downshift, yeah, mine was jacked haha.

I had a few other parts to replace internally besides the normal seals, valves, and clutches. The shaft was broken on the servo piston assembly. The thick brass washer was worn almost completely through on the forward clutch hub and this made for excess wear on the hub so it needed to be replaced as well. The direct clutch drum had excess wear where it runs on the center support and had to be replaced. The rear band and separator plate were also pretty hammered. The Transgo kit came with a new separator plate but everything else had to be sourced. Fortunately for me, a friend runs a transmission shop out of his house and has a bone yard in the back where I was able to find suitable replacements. He sold me new intermediate and rear bands as well.

I didn’t want to take a chance with the torque converter. I took it to a machine shop that came highly recommended by my buddy with the transmission shop. I had them rebuild my converter and had them beef it up. I’m not sure what exactly they did but I told them what I use it for and they did her up like they would a class A RV.

I’m pretty sure I blew out the tranny by overheating it going over the pass and then didn’t really give it a chance to cool down going down the other side with all of the downshifting. I think the shift kit and other corrections made during the rebuild will help avoid this in the future but I also installed a temp gauge just in case. I picked up this one from Glow Shift because the sensor was the right size to fit in the test port on the driver side of the tranny so I didn’t have to do any special splices or drill holes in the pan. I made a custom mount out of some scrap aluminum I had laying around, I’ll admit it’s not my best work considering I was a welder/fabricator but I was in my buddies “wood” shop and didn’t really have all the tools I needed to make it nice. It does the job though, and I was able to reuse the holes from an older bracket that was screwed into the dash by the previous owner.

I think one of the best feelings in the world is spending several weeks working on a big project, you get to the end, you have it all bolted together and you’re ready to test drive. She fires up, you top off the fluids, shift it back and forth between reverse and drive and everything is running smooth. You open up the garage door and pull out and it hardly moves. At least not like it should for the rpms of the engine. I pulled it back in, called my two buddies that were both transmission mechanics, they both had some ideas but nothing definitive.

For three days I tried to trouble shoot the problem and finally figured out that the transmission thought it was in 4 low and that everything was actually fine with the transmission. I was just about to pull that damn thing back out too. It took this long to figure out because it wasn’t in 4 low according to the transfer case. The front tires were not moving the vehicle and I know this because I got stuck in the mud turning it around and had to shift into 4 hi to get out. I finally realized it and shifted it in and out between 4 low, 2 hi, and 4 high for several cycles before it finally kicked out and everything started to work great. I test drove it up the hill and used the manual downshift on the way back down. Everything works, including manual second, it shifts and runs very smooth. I haven’t gotten on it yet but I want to break it in a little bit before abusing it.

I’m not sure what happened exactly, my one buddy said that this happens often enough to not be rare but not common either. The T Case, while original to the vehicle, was never used in 4WD by the previous owner. I bought it in southern CA and the only thing he used the truck for was hauling his fifth wheel camper or huge boat around. He told me the only time he had ever shifted into 4WD was to demonstrate that it worked when he sold it to me, he wasn’t even entirely sure how to do it. He showed me the title that said that he had bought the truck in 2000 with only 15k miles on it so while he wasn’t the original owner he practically was. At this point I’m not going to worry about what caused this, it’s got to be something in the electronics. The truck did sit for 2 years so weird random things are bound to happen. I did change all the fluids in the truck including the T case. For now I’m pretty happy with the rebuild, I’ll try to remember to post an update in a year or so.

This truck has 215k miles on it now, and it has been used as a work horse for pretty much all of that time. I believe that there is no such thing as a mechanical device that never breaks down so these things are bound to happen. I’ll admit there was a long time that I was tired of working on cars but this project actually kinda revitalized some of that passion. I’m getting a little too old to be crawling under a vehicle but once the tranny was on the bench I found the whole process very enjoyable. I tend to be a very meticulous type person and this was definitely up my ally. I always say I have OC, I’m obsessive/compulsive but it’s not quite a disorder. It really helped to have such a detailed video and I wouldn’t have been as confident without it. There are several parts that could be put in either way and the guy in the video is really good about demonstrating the proper way to install each and every piece. I don’t know, we’ll see how it goes over the years, I tend to keep vehicles for 10+ years so I plan to have this for a long time.

0 Comments