This has been quite the year for vehicle repair, some of it is to be expected though. The truck sat for several years while I figured out what I wanted to do with the transmission/transfer case. Shortly after I got the truck back on the road the serpentine belt tensioner pully went out. I was able to limp the truck to a place where I could get a new one, along with a new belt.

I expected to have some issues getting the truck back on the road. Vehicles aren’t meant to sit for long periods of time and bearings in pullies often go bad after a long sit. I have expected things like this and the vehicle has lived up to this expectation so far.

I made it through the summer without any other issues. In October I headed to Kentucky from Western Colorado to help out with the Adaptive Climbers’ Festival and on my way back the water pump went out in the middle of no where Indiana. I stopped at a rest stop and saw steam coming out from under my truck. I looked up auto parts stores and the closest one was 40 miles away in Boonville, IN. I limped the truck there having to pull over every few miles to put the belt back on and add water to the radiator. I had a fully loaded truck carrying all of the kitchen for the festival and left my tools at home. I ended up spending $60 on a new water pump and $120 in tools to do the job in the parking lot, never leave the tools at home. Took me 3-4 hours but I got the old one off and the new one on and back on the road.

On that same trip, as I was almost back to Grand Junction, my power steering pump went out, like I said vehicles don’t like to sit haha. I managed to limp the truck back up to where I was house sitting and had access to a shop and tools, and set out to fix my steering. I had known I was going to have to go through my steering already, the pump was just one more thing to replace. It was kind of a bummer to have that go bad though, I had just replaced it before I left LA in 2018 and it only had a few thousand miles on it. It was definitely before it should have gone out but it is what it is.

I had known for a while that I was going to need to rebuild my steering. The truck had a slight drift going down the road which is common with a warn gear box and/or rag joint. I was starting to get some uneven wear in the front tires which is common with both warn tie rod ends and ball joints. I was going to try and make it through winter and slowly buy all of the parts I needed for a full steering and suspension rebuild but then I got a nail in my tire. Not a big deal but it was in a place where it couldn’t be patched so the tire store warrantied it. Not wanting to replace just one of the two front tires that had uneven wear I replaced both but now I didn’t want to drive on the new tires with the warn steering so I decided to do everything needed to fix the tire wear issue, everything that an alignment would be needed for. A complete steering rebuild for now and the suspension would have to wait till spring.

The truck currently has 225k miles on it and there are going to be warn out parts. I have done these rebuilds on 3 other vehicles, a 1979 GMC C15, my old Taco that I started building my camper for, and a friends Subaru Legacy. It seems like a big project and a lot of money but I am still under $10k into this truck including purchase price and all of the repairs. Somewhere around $1500 in parts this time around.

Before I had left for Kentucky, I had already started buying parts for this rebuild. I knew I was going to have to replace several parts and my philosophy with steering is, if you have a few burned out parts on a truck with over 200k miles, all of the parts are warn and it’s time to replace them all. Steering parts develop slop over time and when they all have slop, they move together, but when you replace one or two parts that are now stiff into the system, they will start to push back against the slopy parts causing them to wear out faster. 224k is a lot of miles, especially considering the truck has always been used to haul a heavy load. It was a bummer to not be able to do the suspension at the same time but it is what it is. I’ll start buying the parts for that with each paycheck until I have everything and then dive back into this for the other half.

I’m not a hard core off roader but I do drive dirt roads often and do find myself in 4-wheel drive often enough to insist on having it on my vehicle. I debated upgrading to some serious ball joints and tie rod ends like something from Kryptonite but given that this truck is a long bed crew cab it’s never going to be a rock crawler. I’ve always had good luck with MOOG parts in the past and they are an upgrade from stock just not a huge upgrade. I did upgrade the tie rod links and steering shaft to those from Cunningham Machine. I’m not in any way affiliated with them, I do feel they make a damn good product. I was a machinist along with being a welder for many years and know quality machining when I see it. The tie rod links were a little pricy, as was the steering shaft, but I believe they are worth it.

My truck is a bit of an oddball, in 1999 GM changed the C/K1500 and I think the C/K2500 to the new body style but left the C/K3500 the same as the Old Body Style (OBS) for a few more years. Finding parts can be interesting sometimes and I often just list it as a 98 when doing a part search. Most aftermarket companies have it figured out but there have been a few that leave me questioning whether or not I’m going to get a part that fits. I have always just ordered the master bushing kit from Energy Suspension in the past but when I looked up my truck only the engine and transmission mounts are listed and even the 98 doesn’t have a master kit because there are too many options in the vehicle. After a lot of internet searching I decided to go with Prothane control arm bushings instead of Energy Suspension because I found confirmation that they would fit my truck and could not with ES. The Prothane’s are a little harder durometer making the ride a little stiffer but I can’t imagine that will make that big of a difference. Both are reputable companies so I think I’ll be happy with them.

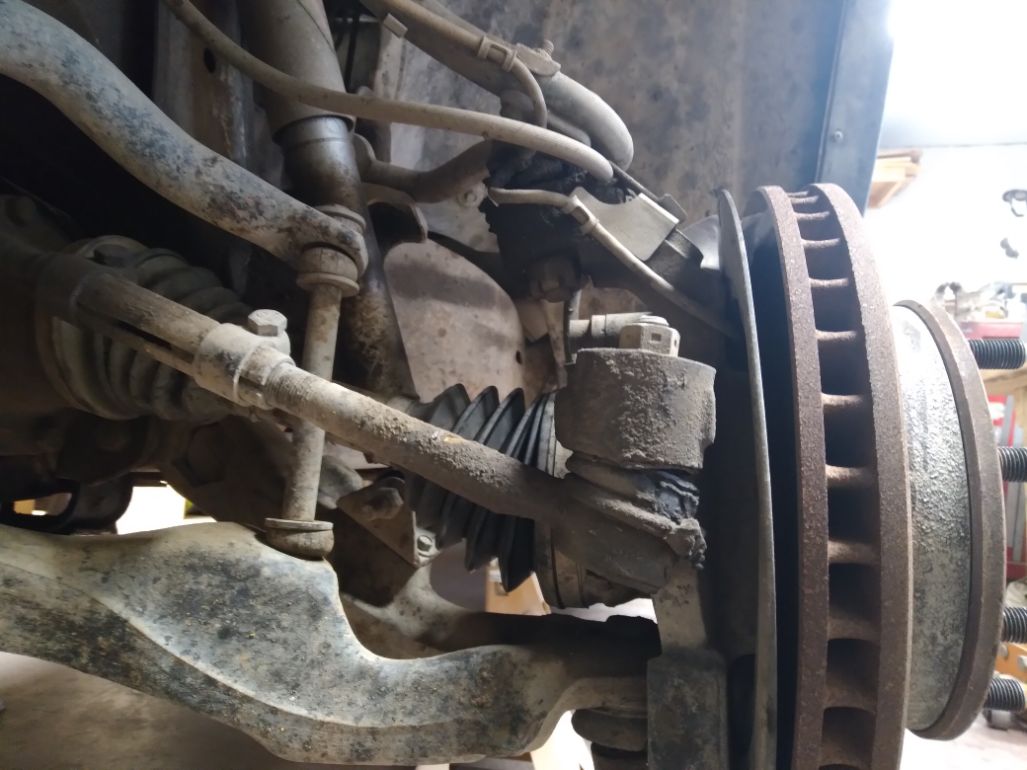

With many parts that I ordered already in, I lifted the truck up and put it on jackstands. I had a friend give the tires a wiggle just to see how bad the parts were and 3 of the 4 tie rods were slopy, one lower ball joint was completely shot and the other lower was a little slopy. The Pitman and Idler arms looked ok, but I replaced them anyways. All of the rubber boots were torn and the rubber bushings were dry rotted. This is all to be expected from a 23 year old truck with 224k miles, it was just time for this rebuild. The shocks were surprisingly in pretty good shape and still appear to be working, they must have been replaced at some point. I plan to replace them over the next year but for now they stayed along with the sway bar link bushings. I plan to upgrade to a Hellwig with poly bushings so I’m not messing with those for now.

I took my time tearing it down, I wasn’t in a hurry as I had another vehicle to drive but I’ve also been working a lot lately starting a new program at work and found myself spent at the end of the day so it was hard to get motivated to work on the truck every day, but I still worked on it a lot. The teardown went well, this truck has only lived in California and Colorado so there is nothing more than surface rust on anything and parts come apart easy enough.

I had done a break job before leaving LA and I surprisingly found that one side was super warn while the other looked newish. I found that the mounting sleaves were bone dry and the one that looked new was sticking really bad. I pulled out the sleaves and hit them with a wire brush, and wire brushed the inside of the slide at well. I greased them up with caliper grease and they seem to glide smooth now. I don’t remember if I greased them when I did the breaks last. The last time I bought new rotors and paid for some nice ones so I got them turned this time. I used ceramics last time because of advice I got from the guy at the parts store, this time around I switched to semi metallic pads from Bosch, they call them SevereDuty. I did some internet research that said ceramics weren’t as good with heavy loads and almost every RV thread said semi metallics were the way to go.

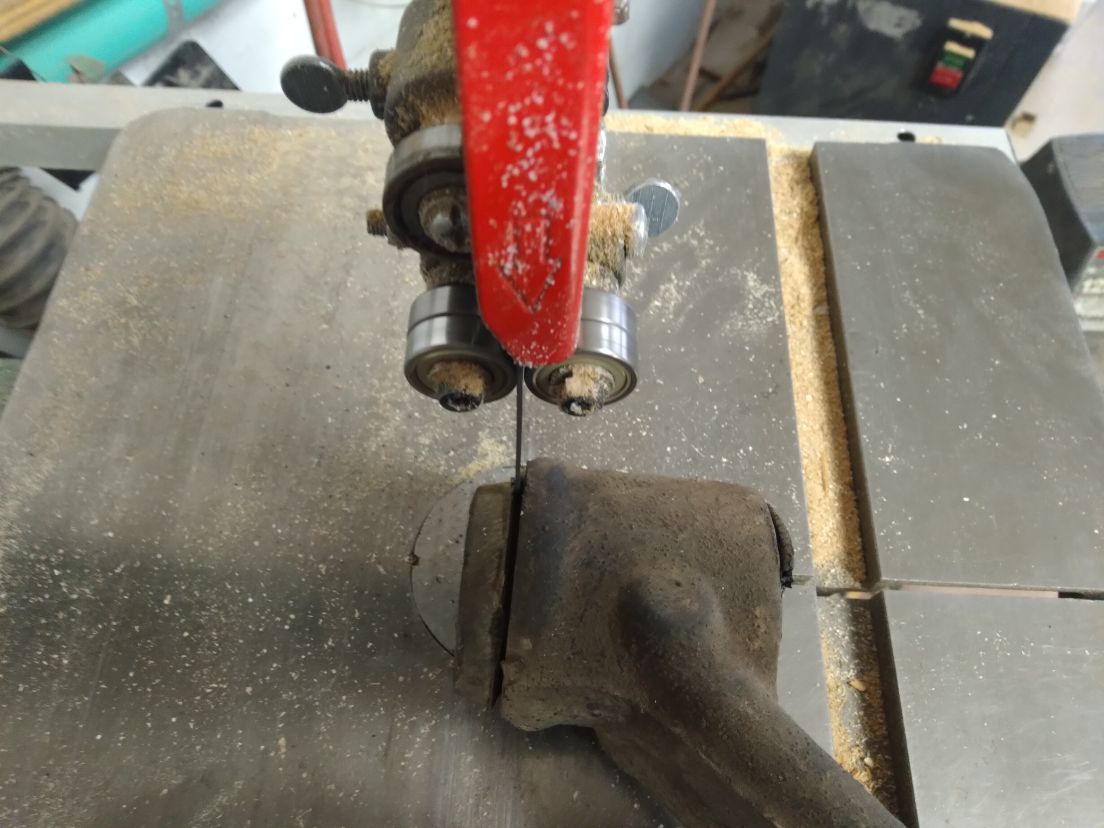

Throughout the tear down I only had two bolts give me a little hassle. The first was the lower control arm bolt on the driver side. The front differential got in the way of the pullout for the bolt, but just barely. I debated pulling the diff, and I really didn’t want to, and thought it just best to cut the bolt off and then buy a new one, threading it through the other end when putting it back together. Turned out, I only needed to cut the very tip of the bolt off to get it to cock enough to the side to not have to cut it off completely.

The other bolt that gave me a hassle was on the hub where it attches to the spindle. The drive axle got in the way for getting a ratchet on it and the head of the bolt was down in a socket that kept me from getting a good grip with a box end wrench. I ended up welding the box end wrench to the bolt head to get it to break free, then I cut the wrench off to spin it off. I found out on the reassembly that I could have removed the drive axle and not had to go through that but oh well, it came off. When torquing the bolts back on at the end of the job I did it without the axle.

Years ago, when I did the steering rebuild on the 79 GMC, I bought a 25ton shop press from Harbor Freight. It’s come in handy so many times over the years and it is a key piece of equipment for a job like this. For the lowers, I started off trying to cut the rubber head off of the bushings so I can push them out the easy way but then remembered they are rubber and rubber can’t withstand 25tons of hydraulic pressure so I just pushed them through without cutting off the heads.

On the uppers, there is no good way to push the rubber out of the metal holder. It seams that Energy Suspension and Prothane both think that burning out the old rubber bushing out of the metal sleave is the best answer so the torch took care of the rubber then a good wire brushing cleaned it all up. On the upper ball joint GM has for a long time riveted it on, this means you have to cut the heads off and push the rivet through. This process grinds the paint off so I painted them to prevent rust. Blue was just the color at the front of the cabinet. I used anti seize instead of the polyurethane lube that comes with the bushings. With all of the old parts out and my control arms cleaned up and painted, I pressed all of the new bushings and ball joints back in making sure to position the grease zerk in the proper orientation on the lower. The new upper ball joint bolts on instead of rivets.

From here it was just a matter of reassembly. Everything went back together relatively easily. The lower control arms were a very tight fit and had to be hammered and jacked into place. But other than that, it all went together easy. Everything was torqued down and buttoned up, then it was just a matter of waiting a week for my alignment because it was Thanksgiving/Indigenes Peoples week and I finished on that Monday. I did drive it a little to see how it felt but don’t want to drive too much till the alignment.

Here’s a completion walkthrough video. At the beginning of the project, I saw that I had transmission fluid all over the underside of the truck. I just rebuilt both the transmission and transfer case and must not have seated a seal properly or had a bad fitting that didn’t seal up. Not sure yet but that will be my next project. They seam to never end but always do at some point. I know it’s not going to be a big deal because I just had both completely apart and didn’t see any cracks or major defects, it should be a simple fix once I track it down.

Update: Well, I knew about the knockouts and that they would most likely need to be removed. When I scheduled my alignment, I asked the guy about them and he told me not to worry about it, said something to the effect of his guy loved Chevys and it wouldn’t be a problem. Then I drop it off this morning and they call me a couple hours later to tell me that it will be 2 hours of labor and that would add $220 to the $85 alignment I dropped my truck off for. I told them no and I would come pick it up and bring it back after I knocked them out. They tried to charge me $55 before letting me pick up my truck. Up until that last part, I would have chalked it up to a misunderstanding and probably still taken my truck back to get the alignment after removing them.

I worked in the trades for many years and understand that things get miscommunicated from time to time. I was bothered that I wasted a day driving my truck down and waited for them to call, but it wasn’t that big of a deal. What really bothered me is that they tried to charge me after I refused their ridicules quote after they told me not to worry about it to begin with. Then, I got back to where I was working on it, pulled the truck in, jacked it up and removed the tires, pulled what I needed and had it all back together in an hour and fifteen min. Having never done it before, and without power tools. I should have just done it when I had the truck in the air the first time.

I did find a couple of tricks for removing them. First, my friend has this tool that had said he shaped around 30 years ago for a job he couldn’t remember. I found that hammering them from the inside out was the most productive and starting at the edge of the hole and rolling it back to the ends of the slot worked well. I fought with the first one, trying to hammer it from the outside in and it was a real bitch. Once I learned the trick, they all came out in about 15 min per side. Definitely not a 2-hour job for an experienced mechanic.

I found another alignment shop closer to where I’ve been working on the truck. My friends have used this other shop for years and say they are solid. I guess I should have just taken the knockouts out when I had it in the air but after talking with the shop and him assuring me, I didn’t need to worry about it. I definitely wasn’t going to pay to get my truck back, or pay an outrageous amount to have it done. I called a few other shops and none of them quoted that high to take the knockouts out. For ten years I have been taking my vehicles to this shop and they have always done a good job or at least I thought they did. I don’t know, the whole thing has left a sour taste in my mouth. Probably wont ever take a vehicle back to them again.

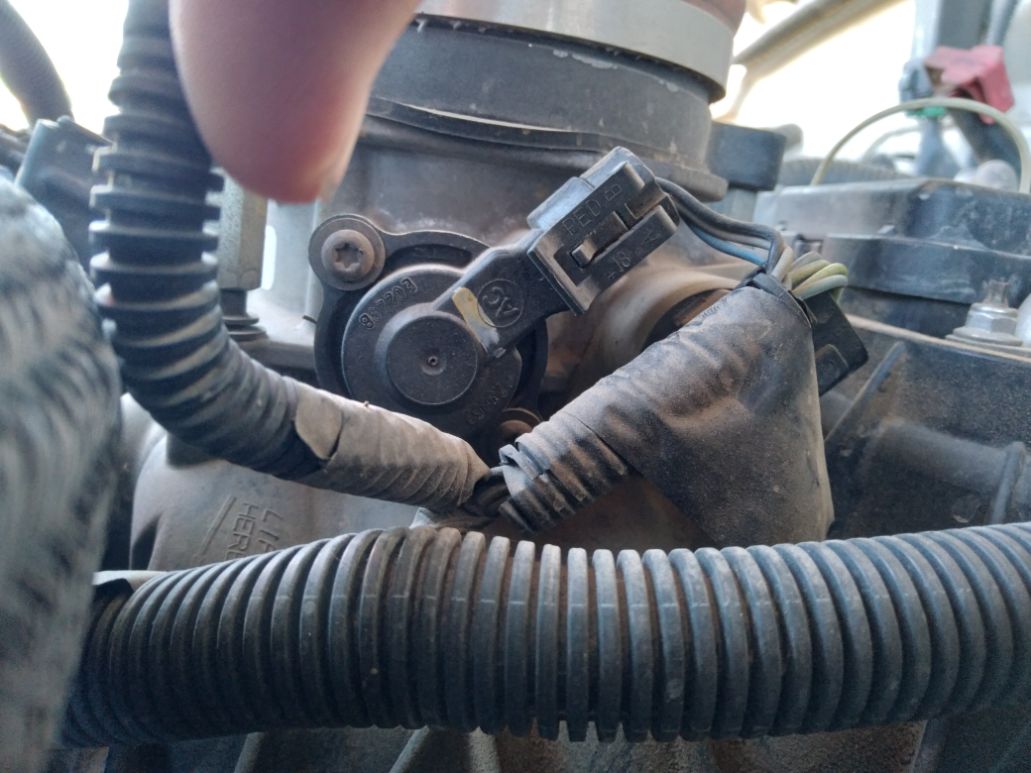

After the transmission/transfer case rebuilds I was having an issue with the transmission shifting really hard but not all of the time. I mean it would slam into gear from time to time. I did some research and it is pretty common for a sensor that goes on the throttle body on the intake to go bad causing this issue. Before leaving for Kentucky, I replaced it and it did make a difference, it happened way less often, but it didn’t fix it completely.

When I pulled apart the T-Case there was a speed sensor ring that had to be pulled off by force. It had stamped into it “DO NOT REUSE” so I wasn’t gentle taking it off. It was only after I got it off damaging it along the way that I realized how hard that part was going to be to come by. I tried a bunch of auto parts store and even the local dealer. The part was discontinued and I couldn’t even find it from a reputable online source. I found it on one website but when I searched reviews for that site, they were all bad. I put it back together with the old beat-up ring but had problems with it ever since. The speedometer would bounce while I was driving and cruise control wouldn’t engage. While I had the steering a part I knew I was going to have to remove the torsion bars which are the one thing in the way for replacing this ring so I went in search. The local dealer was a huge help in tracking it down, they spent 20 min searching the internet for it and found one on eBay (thank you Helman Chevrolet in Delta CO). It was a weird listing and wasn’t clear if it was the right part but it was only $13 so I took a chance. I got it installed and my speedometer and cruise are working right again, and for now it appears the hard shifting is fixed as well.

0 Comments