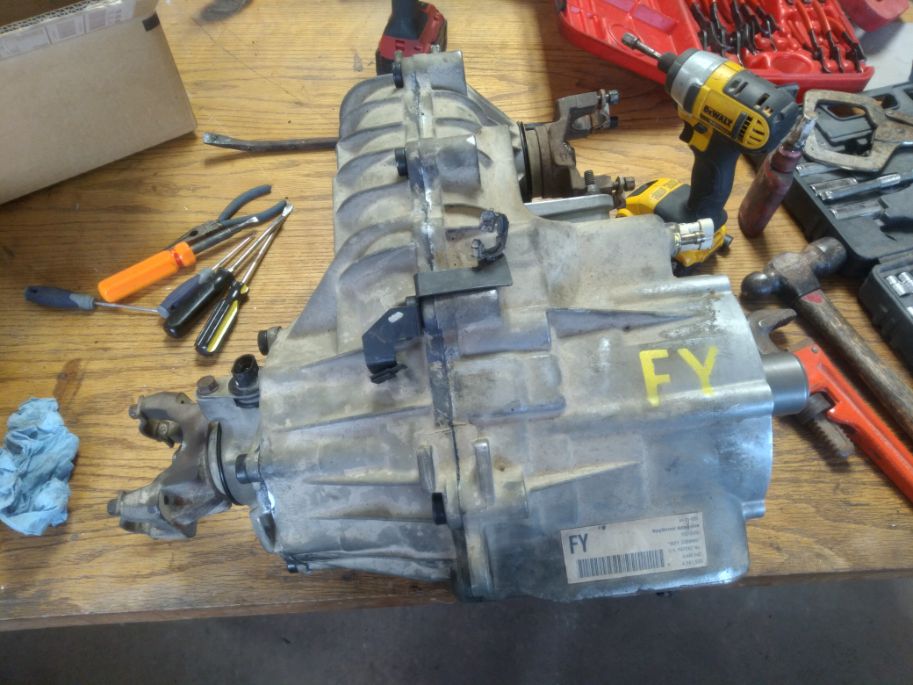

So it turns out that the issue wasn’t resolved with the rebuild of the tranny, at least not the major issue. Where we left off, I got the truck all back together and it was acting like it was stuck in 4 low but after shifting it back and forth between 4 low, 4 high and 2 high I got it running right, temporarily. I thought I had a stuck shifter or some weird glitchy thing that happens when you let a vehicle sit for a couple of years but it turned out to be more. It went a few days of light driving before it stopped working right again and it became apparent I was going to have to address this issue. I did a lot of research and asked on the forums, everything was pointing to either the transfer case or the electronic control module (ECM). The ECM is built into the computer for the engine so I couldn’t just replace it easily. I finally drove it down to my buddies shop 20 miles away, going 20mph. He test drove it and told me to pull the T-case, I got it back up to the house and went to work.

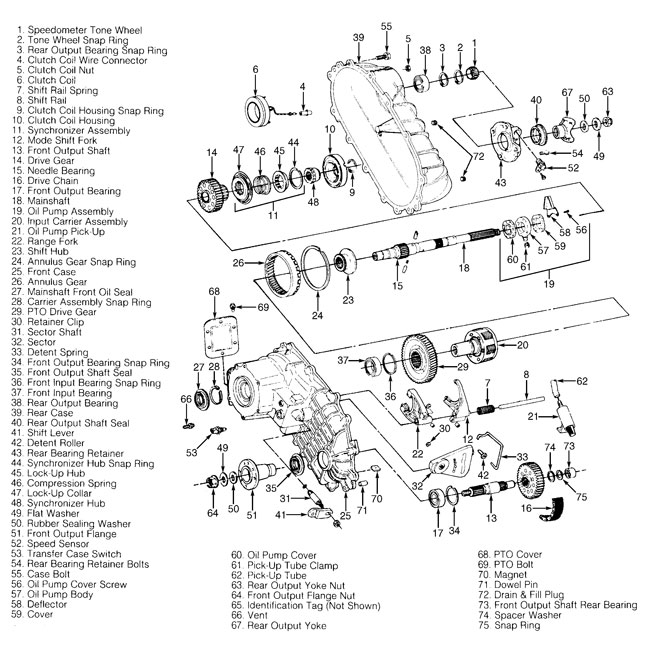

BW4401

Having just reinstalled everything it only took me an afternoon to get the T-case back out. No hemming or hawing about what to remove and none of the bolts were stuck. I got it on the bench and started to tear it down. I always try and find videos for the things I’m working on but I couldn’t find one for this exact transfer case. I watched several on other T-cases that helped give me an idea how it worked, I also found a parts breakdown so I would know what the order was but otherwise I found very little info online on this particular T-case.

These are videos I found helpful, some more than others. Not affiliated with any of these.

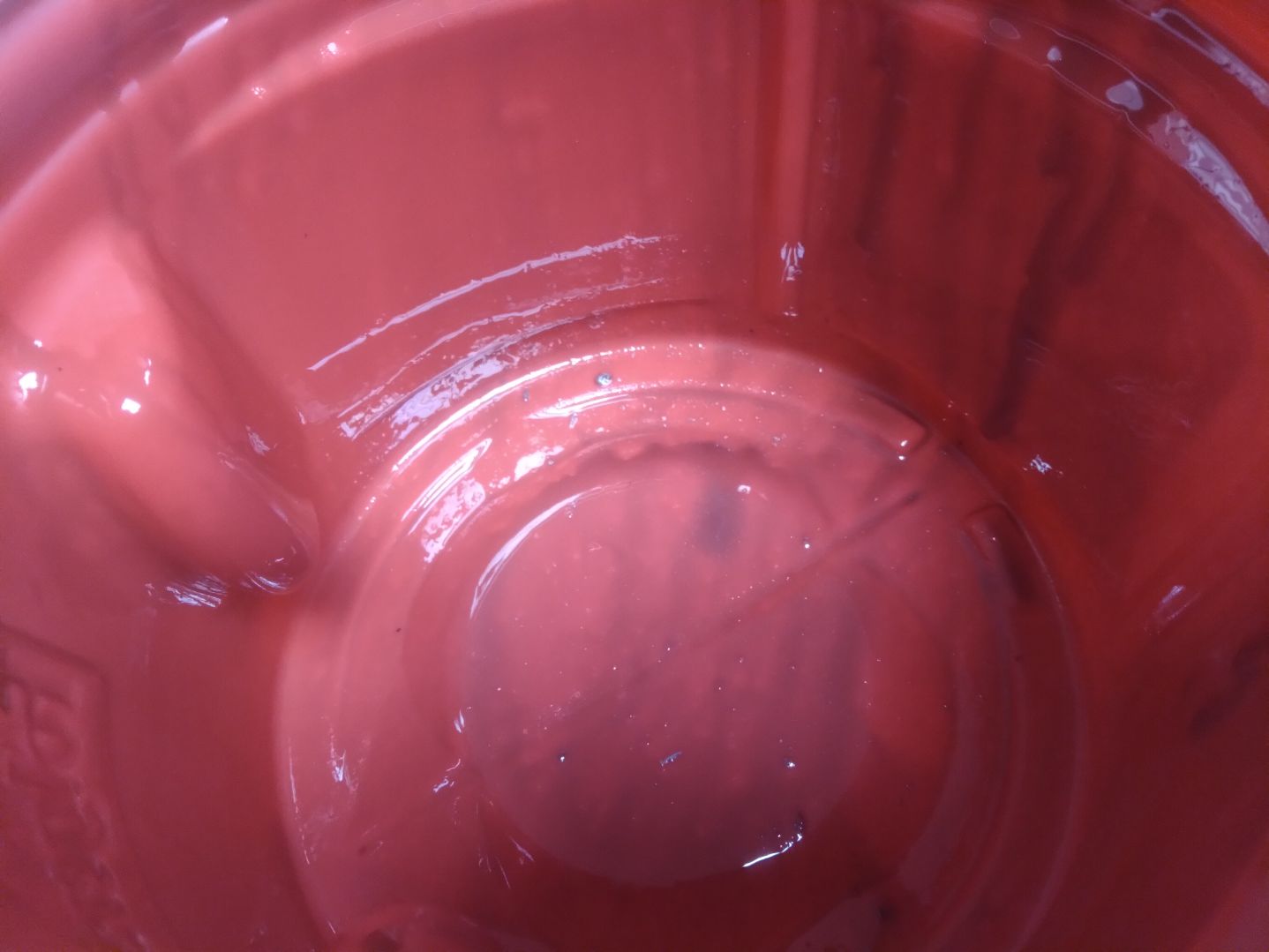

I drained the transfer case when I pulled it for the tranny rebuild, but I just let it drain into a catch pan that didn’t allow me to inspect the fluid. It looked a little dirty as it came out but I didn’t think much about it as it wasn’t the primary objective. I was working under the assumption that the T-case had hardly been used since the previous owner never put it in 4WD. This assumption came from a lack of understanding of how a T-case actually works. Like I said, I’m not a mechanic. This time around I drained it into a coffee can and got a different picture. I had put in all new fluid and only drove it around 40 miles and this is what it came out like, told me a lot.

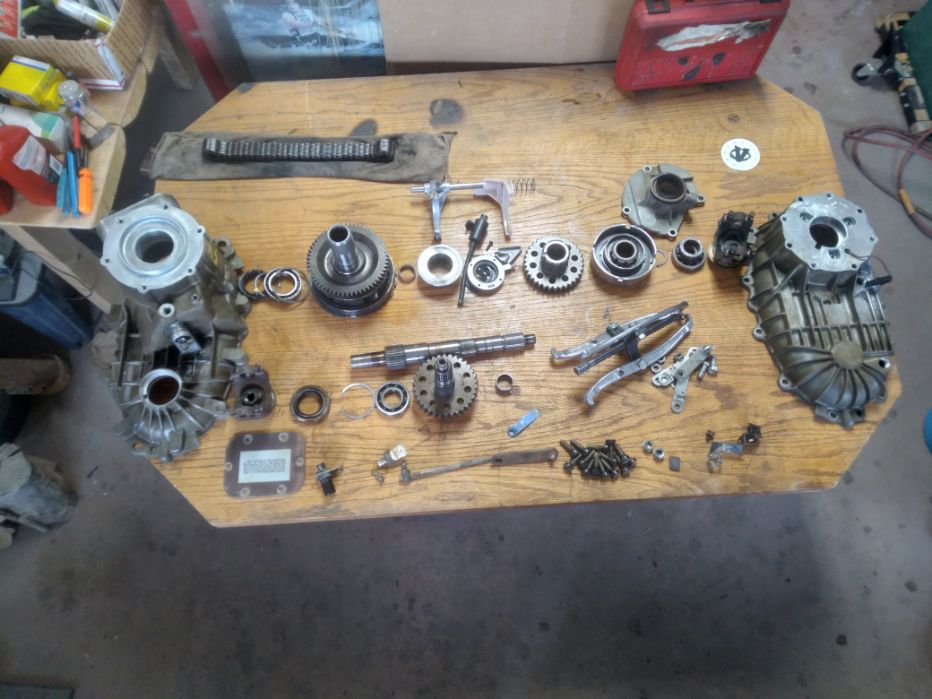

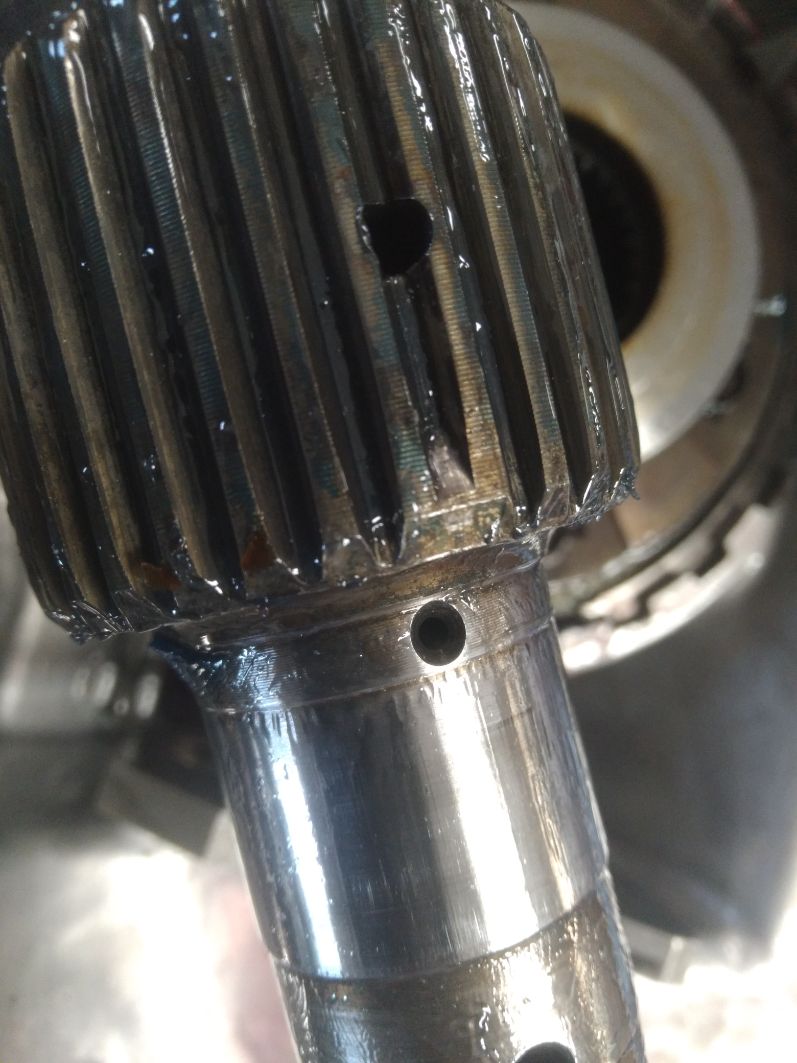

Compared to the transmission the T-case was pretty easy. A lot less parts but also no clutch packs, pistons, or valve bodies. I only had one hang up tearing it down, there’s a speed sensor ring around the output shaft that has “DO NOT REUSE” stamped on it that took some shenanigans to remove. I’ve never had a need for decent snap ring plyers before now, even the transmission didn’t require them. I only had a cheesy pare and they weren’t enough to get the two outer snap rings off, one of them had to be moved to pull that ring. Fortunately, the neighbor across the street had a nice set that he loaned me and I was able to get it all off. Unfortunately, it turns out that speed sensor ring is almost impossible to find and I had to reuse it. Had I known that I would have been a little more carful getting it off. If you decide to rebuild one of these maybe source this part first, #15580305 in case you need it. I did eventually find it but it was going to take a week to get here and I needed to get the truck out of where I was working on it.

After getting it open it was clear that there was a real problem, metal shards were everywhere and the inside was caked with metal dust. Given that the metal was aluminum it wasn’t stuck to the magnet. I worked my way through the case and inspected every piece. I eventually found my issue.

And, I found my smoking gun. When I rebuilt the tranny I was a little disappointed that I didn’t find one for the overall failure but I definitely found it here. This fork moves this hub with a gear back and forth and it kicks the vehicle from high to low and there is normally a nylon piece that buffers the fork from the hub. That nylon is gone and it’s been rubbing metal on metal to the point where it wore all the way through one side. This is likely to be the reason we were stuck on the side of the highway a couple of years ago. There were definitely issues with the tranny and I don’t regret rebuilding it, but I do believe this to be my real problem.

I knew that I was going to have to rebuild the tranny at some point when it stopped manually downshifting into second on the downhills. It’s part of the reason I didn’t bother to troubleshoot the issue before committing to rebuilding it when it went down. The tranny had issues, and after tearing into it I’m glad I went through it. I also added the shift kit and the valve correction kit that makes this a more heavy duty transmission, it will be much more suited to what I’m using it for. I expect to get another 200k+ miles out of these rebuilds and I tend to keep vehicles for a long time so I don’t mind putting in a little money and work.

While I did have a major failure the rest of the parts in the case were in really good shape. The chain and gear setts were practically untouched. With the fork mangled the shifting hub rubbed on the top of the planetary. I ran a scotch bright wheel over it and used a file to clean out the journals. Otherwise the planetary was in really good shape. One of the case bearings was chunky but that comes in the rebuild kit. I replaced the bearings and seals, the broken parts, and a bushing. All told about $200 in parts and I’m up and running again.

The new parts look a lot better than the old haha. Reassembly went pretty easy once I sourced all the parts. My buddy that owns the transmission shop was able to get most of the parts pretty quick but he couldn’t get the speed sensor ring. I thought I had a source online but when I read the reviews on the company they were all 1 and 2 star with horror stories of parts not showing up. I eventually cleaned up the old one.

Well, I did get everything put back in the truck at least once and filled up the fluid. The shifter wouldn’t go into 2 high from 4 low. I test drove it and 4 low worked really well but it would not shift out. I pulled the case back out and cracked it back open. I spent several hours and a few beers trying to troubleshoot to no avail. However, in the morning I took it all the way back down to the planetary and almost missed it but I figured out that two of the splines had a block on the end that prevented the hub from sliding all the way through. The hub had a gapped spline that fit over it. This is why I like videos haha. It was a bit of a pain to have to take it back out but I’m happy I figured it out in the end.

It was a fun project and a few new skills were learned, it was a bit of money spent but I priced out having a mechanic fix the truck and it was going to be around $4,500 for the tranny and/or $2,000 for the T-case if they did all of the work including removal and install. I lost track, but to rebuild both I’m around $2,000 into parts with all of the extras but it also took me over a month to complete. I was able to get some of the parts used from my buddies bone yard which saved me around $300-$400. The way I look at it, these are two major components of the vehicle I don’t have to worry about for a while.

This part is more for me, I figure a year or two from now I’ll be topping off fluids and wondering what I used. When I popped the cap off the radiator, the coolant looked as dirty as the Colorado River. I flushed the system and refilled with Dex Cool. To flush the system I ran water through with the heater running till the water ran clear then filled it up and drove a bit. I ran the same cycle of running water through till it was clear then driving for a bit. I continued this till it was mostly clear after driving. I then drained some water out of the system and filled it back up with the 2 gallons of concentrated Dex Cool and topped off with water. I filled the transmission and transfer case with Valvoline Max life, full synthetic, Dextron VI. I changed the oil in the engine with Valvoline High Mileage, Full Synthetic, 5W-30 when I replaced the rear main seal. I’m not recommending these products, it’s just what I used.

0 Comments